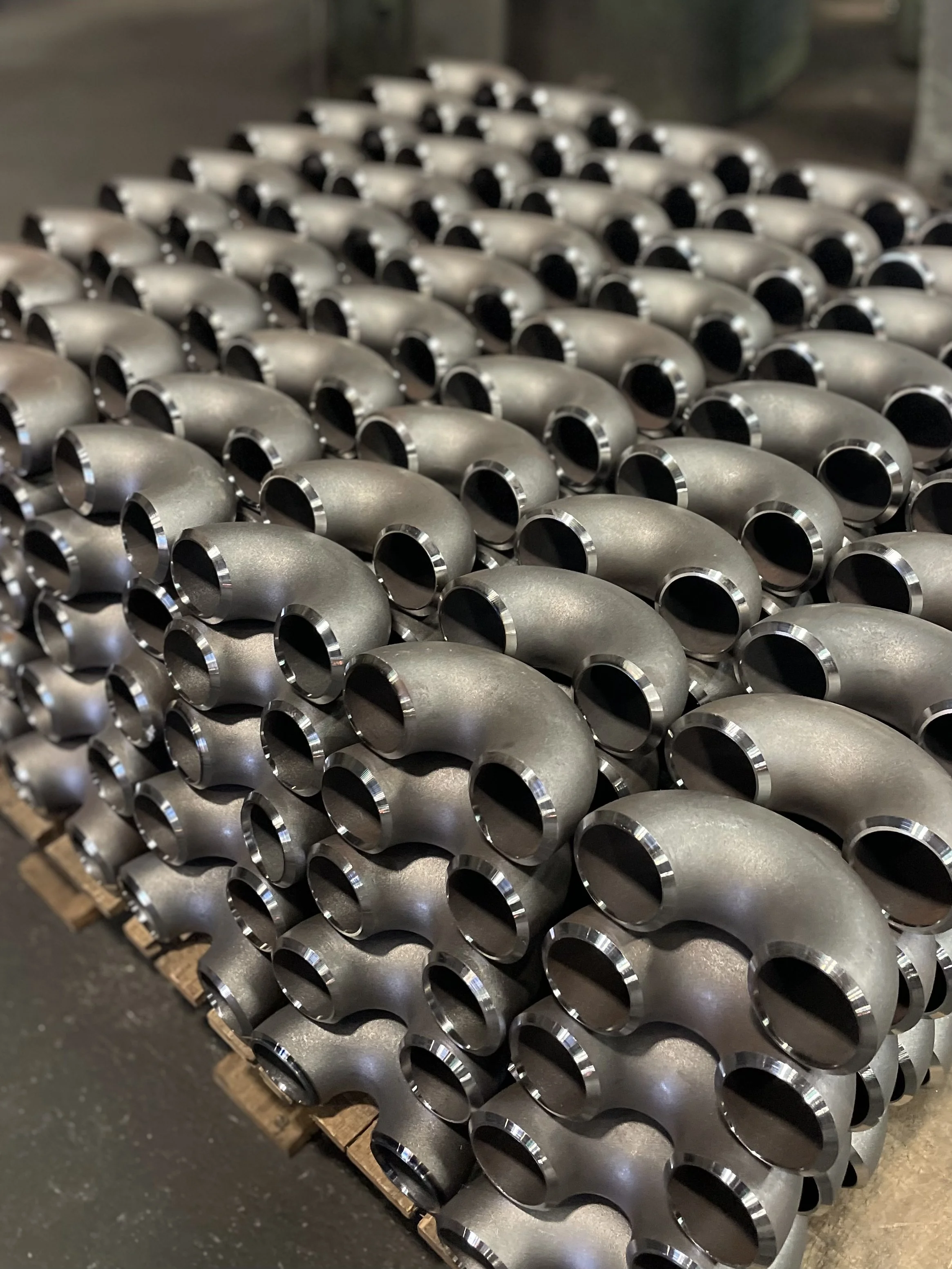

Built to perform. Formed to last.

CloseBend Products

CloseBend’s return bends are precision-formed using high-quality materials to ensure durability, accuracy, and smooth flow in high-performance systems. Trusted by industries for over 50 years, our bends meet strict tolerances and are available in a variety of sizes, radii, and steel grades.

Our hot-formed transition nozzles (swages) are designed to reduce header size, improve fluid dynamics, and to streamline fabrication.

Manufactured in the USA to meet ASME and API standards, these nozzles are ideal for air-cooled heat exchangers and critical piping systems.

At CloseBend, quality isn’t just a promise - it’s our standard. Every product we produce is crafted with precision, inspected for excellence, and made to perform under pressure. From material sourcing to final inspection, we never cut corners.

All of our Products are made in the USA.

Family-Owned Since 1973

CloseBend is a family-owned manufacturing company based in the heart of Oklahoma. For over five decades, we have built our reputation on craftsmanship, customer service, and American-made quality. We are proud to be a trusted partner to industries that keep the world running.

“We guarantee the backwalls of all our fittings, including economizer and wasteheat boiler bends, are never compromised with a less-than-minimum wall condition.”